Room 901-2, 9th Floor, Block C

No.1 Yongshuiqiao Science and Technology Innovation Center

315000 Ningbo City, Zhejiang Province

China

Tel.: +86 0574-87252670

E-mail: hi@passive-edge.cn

Web: https://www.passive-edge.cn

Company profile

PASSIVE EDGE TECH is a new materials technology company specializing in thermal management and thermal energy storage, and we are dedicated to developing 10x energy efficiency solutions, using advanced phase change material (PCM) technology and nano-encapsulation technology to drive sustainable energy transformation. Our founding team, composed of U.S.-educated PhDs with over 20 years of industry experience, brings deep expertise and global perspective.

Technology Overview

We provide high-performance Phase Change Materials (PCM), both organic, inorganic and compound, with an extended operating temperature range from -80 °C to +300 °C. Our two core technologies, both listed in the WIPO Green Technology Database, include:

1)MOFPoly PCM (Nanoencapsulated Phase Change Materials)

Utilizing cutting-edge MOFPoly microencapsulation technology to form leak-proof core-shell particles. The PCM is fully enclosed within a durable outer shell, ensuring reliability. This technology meets a wide range of thermal management application needs, including but not limited to liquid cooling, textiles, and temperature control solutions for electronic devices.

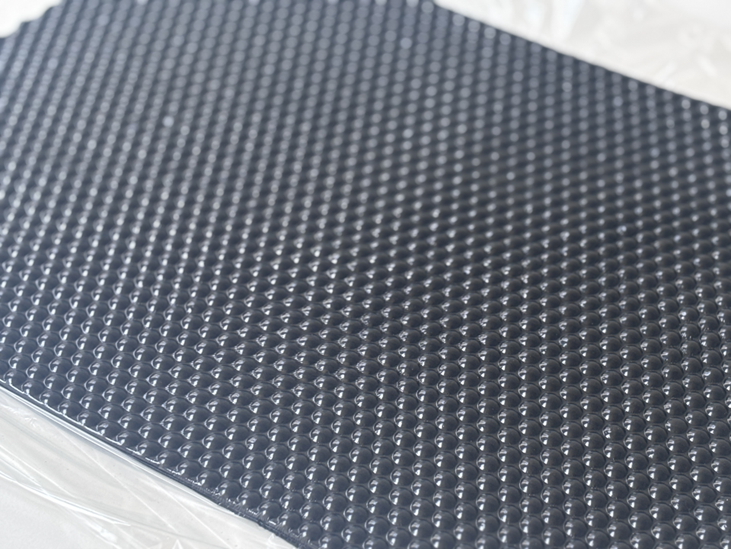

2)UltraST PCM(Ultra-high Thermal Conductivity Shape-Stabilized Phase Change Material)

Overcomes the low thermal conductivity and limited cycle life of conventional phase change materials, while eliminating the potential environmental and health risks associated with fluorinated surface treatments during conventional PCM packaging. It is ideal for applications in industrial and commercial energy storage, building energy efficiency, cold chain logistics & storage, and residential thermal management.

Market Applications

Our PCM technologies are designed for four primary sectors: Data centers & chip cooling, Home & textiles, Cold chain (storage and transportation), and Building thermal management and energy storage (cold and heat).

a) Home & Textiles

Compared to conventional contact cooling or instant-cooling fabrics, textiles embedded with MOFPoly PCM provide long-lasting thermal comfort. With nano mircocapsules, MOFPoly PCM can be incorporated into the textile during fiber processing or post-treatment (e.g., printing or coating), to deliver “cool in summer, warm in winter” functionality.

In home applications, UltraST PCM extends cooling duration to 30+ minutes, offering full-day comfort that surpasses traditional instant cooling solutions.

(b) Cold chain logistics (storage and transportation)

UltraST PCM thermal modules deliver precise and efficient temperature control.

In transportation & storage, compared to conventional packs, they offer faster charging (1/3 of the time), higher conductivity, extended life cycles, and more accurate temperature regulation, more friendly to human health and environment.

c) Building thermal management and energy storage (cold and heat)

UltraST PCM modules integrated into wall assemblies provide passive indoor temperature regulation, maintaining a narrower and more stable thermal range. This reduces HVAC cycling and energy consumption by 20–35%. Combined with renewable energy systems such as solar and wind, UltraST PCM delivers thermal storage solutions with over four times the efficiency of conventional cold/heat storage systems, supporting industrial and commercial energy sustainability.

(d) Data Centers & Chip Cooling

As the AI and AIGC era drives unprecedented computing demand, conventional air and liquid cooling methods face limitations. Passive Edge’s Ultra-high thermal conductivity nanofluid lower chip temperatures by approximately 16 °C, enhancing performance, stability, and overall computing power.